如果您无法下载资料,请参考说明:

1、部分资料下载需要金币,请确保您的账户上有足够的金币

2、已购买过的文档,再次下载不重复扣费

3、资料包下载后请先用软件解压,在使用对应软件打开

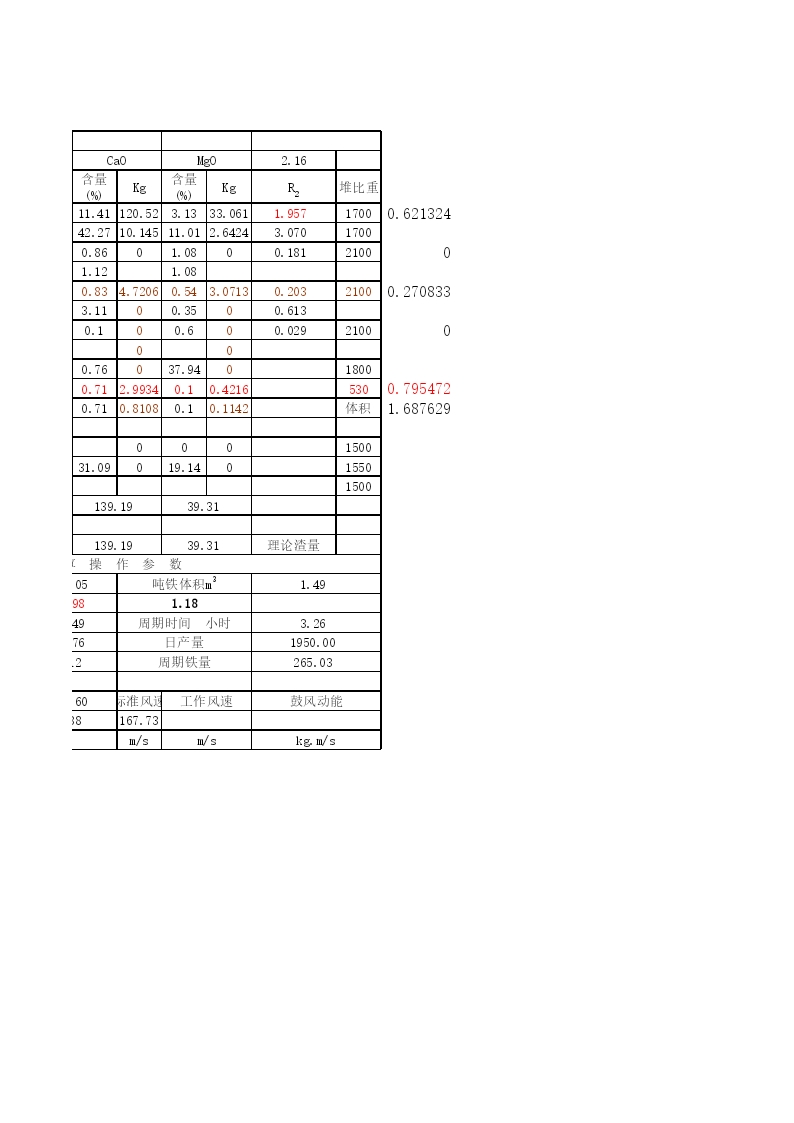

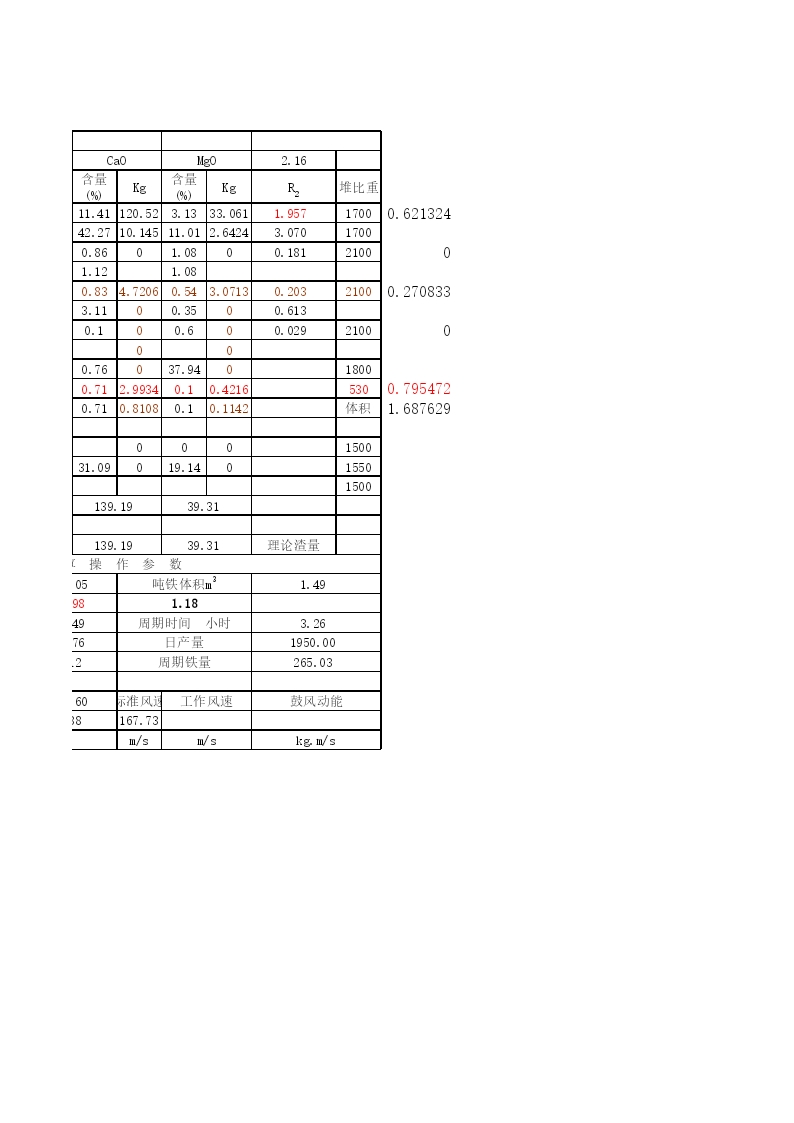

高炉配料计算表55.83矿批Kg21000水分焦kg0综合品位0.00压缩率12%1692.662621原料名称配比FeMnPSSiO2AL2O3CaOMgO2.16手写1692含量(%)Kg含量(%)Kg含量(%)Kg含量(%)Kg含量(%)Kg含量(%)Kg含量(%)Kg含量(%)Kg含量(%)KgR2堆比重厂烧结矿77.0016921302.84厂烧结矿1302.8453.75700.27650.3390.8520.070.09119880.0280.36479526.382.078922.1828.40191212.49162.7247162.7235.4372481.9831700钢渣0.0016920钢渣050003.908520.4800.067013.7704.7042.27011.0103.0701700外球团0.0016920外球团063.390000.0400.00304.76402.18900.8601.0800.1812100本地球1692本地球62.137.0881.4521.121.08球团(厂球)23.001692389.16球团(厂球)389.1662.79244.35356420.2600.0250.0097290.0090.03502447.6629.8096560.973.7748520.712.7630361.164.5142560.0932100蒙古块矿0.0016920蒙古块矿062.5005.0701.00803.1100.3500.613块矿(澳矿)0.0016920块矿(澳矿)063.4050078.8438160.0700.3503.49701.6700.100.600.0292100100.00169200000蛇纹石5.860000000.7300.76037.9401800焦批377000.0250.0094250.5606.825.6364.2616.06020.712.67670.10.377530煤粉150下料批数1煤比0.000.0250.003750.406.810.24.266.390.711.0650.10.15体积5%的蒙古块相当于2%的烧结配比。0.1141028莹石风口总面积风量900000015003月13日480高炉钢渣块全停止使用。白云石0.15715802031.09019.1401550硅石95001500一批料944.6382.750.100.40147.7254.63169.2340.48入铁938.0241.380.100.047.66入渣6.61473.600.36140.0754.63169.2340.48理论渣量生铁成分炉渣成分计算操作参数组成元素含量(%)Kg组成元素含量Kg每批料理论出铁量kg944.63吨铁体积m31.46Fe94.5938.02SiO233.95140.07二元碱度R21.2011.18Si0.363.57AL2O313.2454.63三元碱度R31.497周期时间小时3.31Mn0.54.96CaO41.02169.23四元碱度R41.077日产量1950.00P0.131.29MgO9.8140.48入炉料碱度1.15周期铁量268.95S0.030.30FeO1.004.00C4.544.67S/20.000.00渣铁比kg/t412.60标准风速工作风速鼓风动能0MnO1.024.20硫负荷kg/t0.42167.7282378总计100992.61总计100.03412.60理论矿耗kg/tm/sm/skg.m/s3月10日一车间实际1.19